En

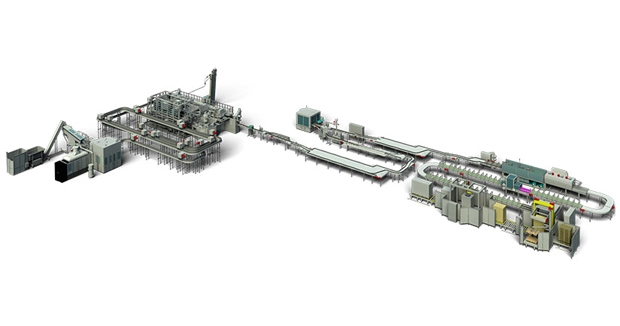

- JQ18(12) TGZ Fluid Filling Machine

- JQ18AKG Grain Filling Machine

- JQ18KG Grain & Fluid Filling Machine

What are you looking for?

We have tank types for different sizes, which are professionally customized according to customer requirements.

The tin container sealing machine has a system controller, which is used to set parameters.

We have professionals to install and set up control variables.

Quality assurance, perfect system, rich experience and guarantee.

Can Seaming for Food and Beverages : Hermetically seals lids onto cans (tin, aluminum, paperboard, PET, etc.), ensuring airtight preservation and leak-proof packaging.

Versatile Container Compatibility : Ideal for packaging food, beverages, sauces, and pet food, supporting high-speed production lines.

High Efficiency and Automation:Automatic multi-head seamers handle large volumes with consistent quality, reducing labor and boosting throughput.

Superior Product Integrity: Produces durable double (or triple) seams that enhance shelf life and maintain product freshness

Customize the seamer chuck and base plate to match the can diameter. Use feeler or clearance gauges to set lifter height, roll-to-chuck clearance, and spring pressure accurately.

Place the filled can into the machine. The chuck holds the lid in place while the base plate lifts the can into proper alignment.

Initiate the first roller to fold the lid curl around the can flange, then activate the second roller to iron and compress the seam, ensuring a tight, leak-proof seal.

Inspect the formed double seam to ensure no wrinkles, bumps, or open seams. Proper tooling and setup help maintain consistent seal integrity.

If you are interested in our food machinery, please contact us. KingQi will get back to you as soon as possible.