En

- JQ18(12) TGZ Fluid Filling Machine

- JQ18AKG Grain Filling Machine

- JQ18KG Grain & Fluid Filling Machine

What are you looking for?

Food machinery is widely applied in the processing of canned pet food for raw material handling, mixing, cooking, sterilization, filling, and sealing. It ensures efficient production, product hygiene, safety, and nutrient retention, while also meeting the high standards required in the pet food industry. Similar precision technology is also used in pet bottle soda filling machines and pet bottle water filling machines, where accuracy and hygiene are equally critical.

Quality control: Strict quality inspection system ensures food safety and meets international standards and regulatory requirements.

Resource utilization: Make full use of fish resources, including by-products such as fish skins and bones, develop high value-added products, and reduce waste.

Environmental sustainability: Introduce energy-saving equipment and environmentally friendly processes to reduce energy consumption and emissions, and promote sustainable development.

These advantages not only strengthen the competitiveness of fish and pet food processing but also reflect the advanced technology shared with pet soda filling machines and soft drink pet bottle machines, which focus on speed, consistency, and reliability. For manufacturers comparing investment, the pet bottle soda filling machine price becomes a key factor in balancing efficiency and cost-effectiveness.

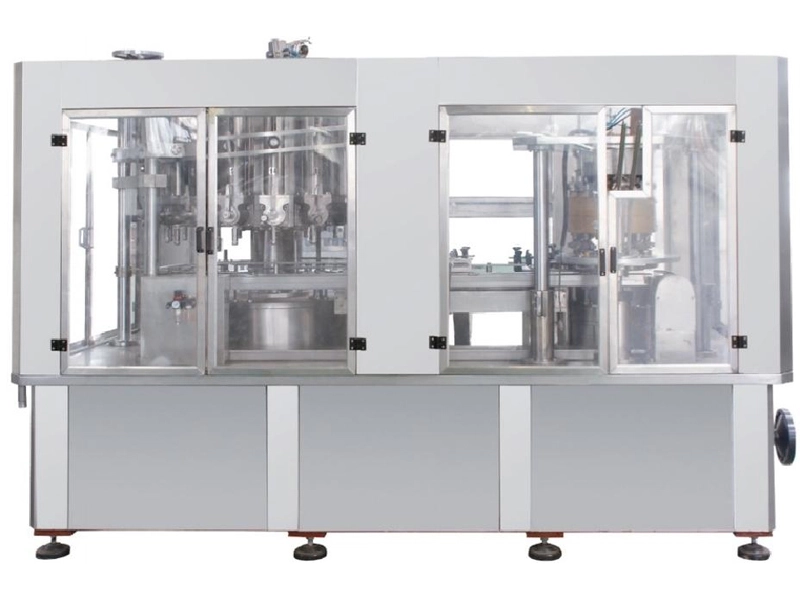

JQ7B18(12)A-250 is designed for filling and seaming high-viscosity products containing soft granules, with content weights under 1000g. Equipped with a pneumatic lid feeding system and HM screen control, this jam jar filling machine is also the top choice for tomato paste and honey producers—offering the same automation principles that drive modern soft drink pet bottle machines.